三个指南对照:

|

机构 |

|||||||||||||||||

|

标题 |

化学仿制药透皮贴剂药学研究技术指导原则(试行) |

Transdermal and Topical Delivery Systems - Product

Development and Quality Considerations Guidance for Industry |

Quality of transdermal patches Adopted guideline |

||||||||||||||

|

时间 |

2020年12月 |

November 2019 |

Date for coming into effect - 17 June 2015 |

||||||||||||||

|

目录 |

一、概述 二、透皮贴剂仿制药药学研究的整体思路与要求 三、处方与制备工艺研究 (一)处方 1.原料药 2.辅料与材料 3.标识 (二)工艺 1.典型工艺步骤 2.工艺研究 3.批量 四、质量与特性研究 (一)一般要求 (二)特性质量研究 1.体外释放 2.体外透皮 3.体外黏附性能 4.药物残留 5.制剂中原料药热力学稳定性 6.黏合剂杂质 7.热效应 8.基质结构的微观评估 五、稳定性研究 六、名词解释 七、参考文献 |

I. INTRODUCTION II. BACKGROUND A. General B. Regulatory

Status III. TDS PRODUCT DEVELOPMENT A. Quality

Target Product Profile B. Critical

Quality Attributes 1. TDS

Product 2. Drug

Substance 3. Excipients

and Components 4. Identifying

Labeling C. Product

and Process Development IV. INFORMATION TO BE SUBMITTED IN AN APPLICATION A.

Pharmaceutical Development 1. Batch

Formula 2.

Expectations for Registration/Exhibit Batches 3. Product

Characterization Studies 4. Proposed

Manufacturing Changes B.

Manufacture C. Control of

TDS Product D. Additional

Stability Studies V. SPECIAL TOPICS A. Product

Adhesion Considerations B. Product

Storage and Disposal – Labeling Considerations |

Executive summary 1. Introduction (background) 2. Scope 3. Legal basis 4. New applications 4.1.

Description and composition of the drug product 4.2.

Pharmaceutical development 4.2.1.

Therapeutic objectives and principle of the delivery system 4.2.2. Active

substance 4.2.3.

Excipients 4.2.4.

Formulation development 4.2.5.

Stability programme development 4.2.6. In

vitro and in vivo drug product performance 4.2.6.1. In

vitro drug release / dissolution 4.2.6.2. In

vitro skin permeation studies 4.2.6.3.

Adhesive properties 4.2.6.3.1. In

vitro adhesion tests 4.2.6.3.2. In

vivo adhesion studies 4.2.6.4.

Pharmacokinetic studies 4.2.6.5.

Product batches used in clinical studies 4.2.7.

Manufacturing process development 4.2.8.

Container closure system 4.2.9.

Administration 4.3.

Manufacture 4.4. Control

of excipients, including layers and liners 4.5. Drug

product specifications 4.6. Control

strategy 5. Requirements to support a generic or abridged

application 5.1. General

remarks 5.2.

Development pharmaceutics 5.3.

Comparative quality and clinical data requirements 5.3.1.

Quality 5.3.2.

Clinical 6. Variations applications Definitions References Annex 1 (In vitro permeation studies) |

||||||||||||||

|

定义和范围 |

透皮贴剂(Transdermal Patch)系指用于完整皮肤表面能将药物输送透过皮肤进入血液循环系统起全身作用的贴剂。 本指导原则主要针对透皮贴剂化学仿制药。 |

Transdermal delivery systems are designed to deliver an active

ingredient (drug substance) across the skin and into systemic circulation,

while topical delivery systems are designed to deliver the active

ingredient to local tissue. This guidance provides recommendations to applicants

and manufacturers of transdermal and topical delivery systems (TDS)

regarding the pharmaceutical development and quality information to include

in new drug applications (NDAs) and abbreviated new drug applications

(ANDAs). |

A transdermal patch, which may also be

considered a Transdermal Drug Delivery System (TDDS), is defined as a

flexible, multi-layered, pharmaceutical single dose preparation of varying

size containing one or more active substances to be applied to the intact

skin for systemic absorption. This guideline considers the general requirements

concerning the development and quality of a transdermal patch for all new

marketing authorisation applications and variations. In addition, specific

guidance is provided concerning the data requirements to support generic or

abridged applications. |

||||||||||||||

|

全身作用 仿制药 |

全身作用、局部作用 新药、仿制药 |

全身作用 新药、仿制药 |

|||||||||||||||

|

分类和结构 |

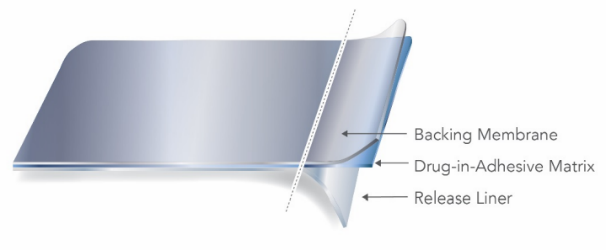

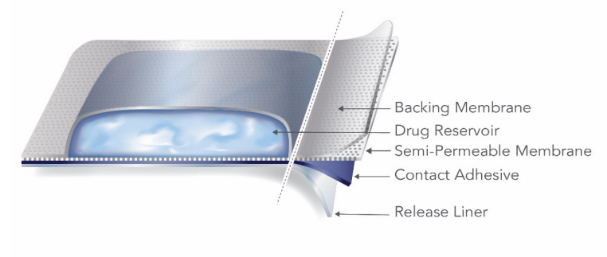

透皮贴剂按照含有活性物质的支撑层的结构特点通常可分为骨架型(Matrix Type)和储库型(Reservoir Type)。 骨架型贴剂通常由背衬层(Backing Membrane)、含有活性物质的支撑层(Drug-in-Adhesive Matrix)、黏合层(Contact Adhesive)、保护层(Release Liner)等组成。 储库型贴剂通常由含药液态或半固态凝胶用热封区域截留在背衬层和控释材料之间制成。 |

Matrix type TDS contain one or more active ingredients dissolved or

partially suspended in a mixture of various components, including adhesives,

penetration enhancers, softeners, and preservatives, and are typically

manufactured using solvent, hydrogel, or hot melt-based practices.  Reservoir type TDS similarly contain a variety of components in liquid

or semi-solid form; however, reservoir type TDS utilize a heat-sealed area to

entrap the active gel between the backing membrane and a microporous

membrane.  |

A transdermal patch includes a backing sheet,

impermeable to the active substance and normally impermeable to water. The

releasing surface of the patch is covered by a protective liner to be removed

before applying the patch to the skin. Alternatively, absorption may be limited by

incorporating or dissolving the active substance in a (semi solid) reservoir,

with a membrane to control the release and the diffusion of the active

substance(s) from the patch. |

||||||||||||||

|

制剂质量考虑 |

透皮贴剂的质量研究一般应包括但不限于以下研究:性状、鉴别、含量、单位剂量均匀性、有关物质、剥离强度、保护层剥离力、初黏力、持黏力、冷流、体外释放、原料药析晶、包装完整性、残留溶剂、微生物限度(如适用)、透皮促进剂含量/抗氧剂含量/含水量(如适用)等。 |

Quality Target Product Profile:

CQAs typically include appearance (such as lack of

visible crystals), dimensions, uniformity of dosage units, assay, permeation

enhancer content, impurities and degradants, in vitro drug release profile,

preservative/antioxidant content (if present), peel adhesion, tack, release

liner peel strength, shear strength, cold flow, residual solvents, residual

monomers, microbial limits, and package integrity. |

The development of the drug product should be

described with respect to the defined quality target product profile,

employing suitable tests to characterise and control the critical quality

attributes, including adhesion properties, factors affecting ease of

administration and duration of use, and product performance (dissolution, in

vitro drug release, in vitro skin permeation). In terms of quality in relation to efficacy: · The active substance content, formulation,

patch size and thickness should be justified by a sound rationale, in vitro

quality testing and clinical evidence, described by a clear narrative of

product development. In terms of quality in relation to safety: · Those quality elements that may influence

the safety of the drug product such as material specifications,

qualification, identification and control of residual solvents and impurities

should be discussed. The risks of dose dumping, leakage from reservoir,

residuals and product residues should be discussed. Cross reference to

relevant non-clinical or clinical data should be given. In terms of quality with respect to the

administration and use: · The adhesive properties of the drug

product should be fully discussed and characterised, by both in vitro and in

vivo testing. The adhesion / cohesion balance should be considered, with

respect to minimisation of cold flow (formation of a “dark ring” around the

transdermal patch in use), satisfactory elasticity and the avoidance of

detachment, or edge lifting throughout use and skin damage following removal. |

||||||||||||||

|

原料药质量考虑 |

应对可能影响透皮贴剂性能及生产可行性的原料药的理化及生物特性进行研究,特别是影响递送速率的性质,如分子量、熔点、分配系数、pKa、溶解性能和pH值等。 原料药的其他特性,如粒度分布、晶型与晶型稳定性等,应根据产品性能进行评估和论证,选择其特征指标进行研究。 |

Selection of a drug substance should be justified

based on the physicochemical and biological properties of the drug substance

that can influence the performance of the TDS product and its

manufacturability. In particular, properties that influence the rate of

delivery, such as molecular weight, melting point, partition coefficient,

pKa, aqueous solubility, and pH, should be considered. Other characteristics

of the drug substance such as particle size, crystal form, and polymorphism

should be evaluated and justified in terms of product performance. |

Active substance physicochemical and biological

properties that determine the capability and / or influence the rate and

extent of transdermal delivery and the manufacturability and stability of the

drug product should be identified and discussed. Such properties include

molecular weight, partition coefficient, melting point (boiling point if

applicable), pKa, solubility and pH effects, as well as physical properties,

such as particle size and polymorphism, if the active substance is present in

the solid state in the drug product. The target physical state of the drug substance, e.g.

solute, suspension, and the degree of saturation or supersaturation are

critical quality attributes and should be justified in terms of product

efficacy and safety, supported by evidence of the means by which the target

state is achieved during manufacture and its stability during storage. The risks of precipitation / particle growth / change

in crystal habit, or other active substance characteristics likely to affect

the thermodynamic activity, arising from changes in temperature and on

storage should be assessed and appropriate tests included in the stability

studies. These properties could be inter-related and might need to be

considered in combination. |

||||||||||||||

|

辅料质量考虑 |

透皮贴剂所使用的辅料与材料可能包括各种黏合剂、透皮促进剂、增溶剂、增塑剂、增黏剂、抗氧剂、稳定剂、交联剂、结晶抑制剂、控释膜、背衬材料、保护层等。 对于黏合剂,研究者应根据其用途考虑以下属性:分子量、多分散性、光谱特性、热力学特性、特性或复合黏度、残余单体与二聚体、残留杂质(如催化剂和引发剂)、残留溶剂、重金属等。其它需要考虑的属性包括黏弹性能,如弹性模量G'、黏性模量G,蠕变柔量J等。此外,应对黏合剂可能影响终产品质量(如体外释放、体外透皮和体外黏附性能等)的功能性相关指标进行研究。 对于膜性材料,应根据其不同用途进行相关研究。如控释膜、背衬材料、保护层等应对外观、柔韧性、抗拉强度、孔隙率、密封性、化学惰性等特性进行研究。 而对于控释膜型透皮贴剂,还应研究控释膜的适用性与性能。必要时,还应对膜性材料的提取物和浸出物进行研究。 对生产过程中使用但最终去除的物料(如临时膜材、溶剂等)进行必要的研究,评估上述物料组分转移并残留至终产品中所导致的质量及安全性风险。 |

Excipients and components used in TDS can include

various adhesives, permeation enhancers, rate controlling or non-rate

controlling membranes, solubilizers, plasticizers/softeners, or tackifiers,

all of which can influence the quality and performance attributes of TDS. For example, when qualifying the adhesives in a TDS

product, an applicant should consider the following attributes: · For adhesive polymer(s) as raw

material(s): molecular weight, polydispersity, spectroscopic analysis (e.g.,

infrared radiation (IR) absorption), thermal analysis, intrinsic or complex

viscosity, and measurement of residual monomers, dimers, solvents, heavy

metals, catalysts, and initiators. · For adhesive as a laminate (in the absence

of the active ingredient and other excipients): residual solvents, peel,

tack, shear, and adhesion. · For adhesive in the final product (along

with drug substance and other excipients and components): identification,

residual monomers, dimers, and solvents; impurities; loss on drying; and

uniformity. Other properties to be considered include the viscoelastic

properties (such as elastic modulus (G’), viscous modulus (G”), and creep

compliance (J)), and functional properties including, but not limited to,

peel, shear, adhesion, tack, in vitro drug release, and in vitro drug

permeation. |

The relevant characteristics of the layers (backing

layer, the release liner, rate controlling membranes and adhesive liner),

such as appearance, flexibility, tensile strength, porosity, occlusion and

chemical inertness, and the other excipients should be discussed. This

information can be used, as appropriate, to justify the choice and quality

attributes of the excipients, their specification and safety (3.2.P.4.4 and

3.2.P4.6) and to support the drug product specification (3.2.P.5.6). The composition and relevant characteristics of

excipient mixes, e.g. adhesive solutions or suspensions, should be provided

and characterised, including viscoelastic properties, if appropriate.

Processing aids, including temporary lamination layers and solvents employed

during manufacture, which are subsequently removed, should be identified and

described. |

||||||||||||||

|

包装系统质量考虑 |

|

|

This should include the choice of materials,

protection from moisture, oxygen and light, drug product compatibility and

safety. The primary package should normally contain only a

single transdermal patch. The backing layer and release liner should not be

considered a part of the container closure system. Appropriate tests should be included in the stability

study protocol to ensure that the suitability of the container closure system

is satisfactorily assessed throughout shelf-life. |

||||||||||||||

|

标签要求及质量考虑 |

标签标识一般印在透皮贴剂的背衬层上,至少应包括产品名称和规格。 对于管制类药物,应根据监管要求,确保在贴剂的全生命周期均具有足够的对比度和辨识度,可采用机械模拟试验(如摩擦等)与化学模拟试验(如喷淋、洗涤剂清洗等)来考察标识持久性。 应对标签标识的印刷材料与透皮贴剂之间的相互作用进行研究,以评估其对透皮贴剂的质量及安全性的影响。 |

Applicants are encouraged to incorporate a

representative label early in development to assure the labeling process or

inks utilized for printing do not interact with the TDS product, and to

properly assess inks during extractable and leachable studies. The

identifying label is typically placed on the backing membrane of TDS and

should, at minimum, include the product name and strength. |

The SmPC, package leaflet and labelling should fully

address the correct administration of the transdermal patch and include any

necessary warnings for the safe use of the drug product. |

||||||||||||||

|

生产工艺及过程控制 |

1.典型工艺步骤 透皮贴剂典型的生产步骤/单元操作通常包括但不限于:混合、涂布干燥、复合层压、分切、印刷、裁切和装袋。 2.工艺研究 透皮贴剂工艺较复杂,应加强中间体的研究和控制,应对可能影响产品关键质量属性的物料特性、工艺步骤及工艺参数进行研究。 混合工艺可能影响产品的含量、原辅料稳定性、含量均匀度、微观形貌和黏合剂的物理性能等。 需考察的工艺参数通常有物料加入顺序、混合速度和时间、温度、再分散或再循环条件、脱气条件等,需考察的物料属性通常有原料药粒度、晶型、物料的流变特性、溶剂型物料中固形物含量百分比等。 涂布干燥工艺可能影响产品的含量、含量均匀度、微观形貌、药物释放、稳定性、残留溶剂、残留的黏合剂杂质以及黏合剂基质的物理性质等。需考察的工艺参数通常有生产线速度、泵或螺杆速度、区域温度、空气流速、干燥空气的温湿度等。 需考察的物料属性通常有涂布混合物的流变性、均匀性以及涂布混合物中的溶剂和黏合剂杂质含量等。此外,还应对为补偿干燥期间的挥发而导致的原辅料过量投料进行研究。 应当对单元操作之间任何中间体的存放时间及条件进行考察。 |

Typical TDS manufacturing steps/unit operations are

listed below (a non-exhaustive list). For processes that incorporate these

steps, the applicant should describe how each operation and associated

controls were developed, addressing the considerations below, specifically,

the CQAs that may be impacted by the operation, and the relevant process

parameters and material attributes that may impact the output of each operation: · Mixing: Mixing operations produce bulk

mixtures for the coating step. Mixing can impact CQAs such as assay,

stability of drug substance and/or excipients, content uniformity,

microscopic appearance, and physical properties of the adhesive. The control

strategy should address the impact of equipment design, order of material

addition, and process parameters (such as mixing speeds, mixing times,

temperatures, redispersion or recirculation conditions, and deaeration

conditions) on CQAs, and should be justified, as necessary, based on

development studies. CMAs that can impact mixing include drug substance

particle size, polymorphic form, raw material rheological attributes, and

percent solids for materials supplied in solvent-based mixtures. · Coating is the application of a mixture to

a substrate. Depending on the equipment used, coating can impact CQAs such as

content uniformity and microscopic appearance. Though CPPs are equipment

dependent, firms should demonstrate that the control strategy (e.g., process

parameters to be controlled) is adequate to ensure content uniformity and

microscopic appearance for the full duration of the coating operation. CMAs

that can impact coating include the rheology of the bulk mixture and

within-roll uniformity of the substrate to be coated. · Drying involves the removal of solvent

from the mixture following the coating process. This process step can impact

CQAs such as assay, permeation enhancer content, antioxidant content, water

content (for hydrogels), content uniformity, microscopic appearance, drug

release, product stability, residual solvents, residual adhesive impurities,

and physical properties of the adhesive matrix. Therefore, CPPs for drying

that may need to be considered during process development include line speed,

the pump or screw speed, zone temperatures, air flow rates, temperature of

the drying air, and humidity of the drying air. Process development should

also consider the CMAs that can impact drying such as solvent and adhesive

impurity content in the bulk mixture. Applicants should also provide data to

justify any drug substance overage or excipient excess that may be needed to

compensate for any evaporation during drying. · Lamination involves the combining of

multiple layers of a given transdermal system design into a single common

laminate. Applicants should provide development data for corona treatments if

such a process is used to bond the adhesive to a backing film or rate-controlling

membrane. · Slitting and Printing: The bulk product is

typically slit longitudinally into narrower rolls of laminate for further

processing. Slitting and printing are typically low risk steps; however, if

certain aspects of the printing processes, e.g., excessive penetration depth

or heat input, can adversely affect product quality, then printing processes

should be characterized and controlled. · Converting and pouching: Converting and

pouching typically involve cutting a continuous laminate into individual

units and sealing the unit in a heat-sealed pouch. CQAs affected by these

processes include usability of the product (e.g., the ability to remove a

release liner) and pouch integrity. Common CPPs for these steps include heat

sealing temperatures and dwell times. · Curing: Some TDS have processing steps to

complete a curing reaction after drying or pouching. Curing time and curing

conditions are common CPPs for this step. Curing should be completed before

batch release testing if curing could impact test results. · Hold times: Hold times must be defined and

justified for in-process materials held between unit operations. Applicants

should use a risk-based approach to determine which CQAs to monitor during

hold time studies. · Other considerations: Tubing and other

product-contact equipment must be qualified as non-reactive, non-additive,

and non-absorptive. The selection of the tubing and certain

product-contacting equipment should be risk-based, i.e., dependent on the

duration of contact, process temperature, solvent system, material

considerations, clearance of leachables during manufacturing, and clinical

use considerations. In-process controls (IPCs) for TDS are an integral

part of the control strategy. The description of the proposed IPCs should

address the following: · At the mixing stage, IPCs can provide

assurance of assay, viscosity, uniformity, and pH for aqueous mixtures. If

multiple samples are taken from a dispersed mixture, applicants should

specify the mean, range for individual samples, and percent relative standard

deviation. · IPCs for coating, drying, and lamination

can provide assurance of uniformity across the laminate and throughout the

run. · For converting and pouching, IPCs can

provide assurance of pouch integrity, product placement within the pouch, and

product appearance. An automated system can perform in-process checks for

product appearance in lieu of human operators if the automated system is

demonstrated to be suitable for the intended task(s). |

The following non exhaustive list should be

discussed: · The preparation and homogeneity of the

bulk drug containing and if applicable the bulk non-drug containing adhesive

masses; · The coating process, including those

parameters that control the layer thickness; · Drying, curing and where applicable the

removal of residual solvents, including water for aqueous based blends; · Laminations steps; · The storage and handling of intermediate

rolls; · Roll conversion to transdermal patches;

and · Primary packing. |

||||||||||||||

|

制剂的规格 |

目前国内已上市透皮贴剂的规格有载药量、载药量/贴剂面积、递送速率等多种表达方式,而在欧美国家目前通常以递送速率,即递送量/释放时间(例如,**mg/天或**mg/h 或**mg/24h)表示,该递送速率可源于 PK 数据或残留药物分析数据。 |

The strength of a transdermal system should be

expressed as a rate (e.g., XX mg/day), whereas the strength of a topical

system should be expressed as a percent total drug load. For transdermal

systems, the strength can be derived from and supported by either PK data or

by residual drug analysis performed on used transdermal systems. The first

approach involves the derivation of a clearance (Cl) value from absolute

bioavailability of the drug and multiplying that by the concentration (Css)

at the steady state. The second approach involves the measurement of the

amount of drug left in the transdermal systems at the end of the wear period

and dividing the “consumed amount” by the wear period. |

Strength, as the mean dose delivered per unit time,

normally mass delivered in vivo per 24 hours. |

||||||||||||||

|

产品特性研究-原料药热力学稳定性 |

应确认原料药的热力学稳定性,评估生产和储存过程中析晶、沉淀或成盐的风险,以及对产品性能的影响。析晶研究可选用显微镜和光度法,以及 DSC、XRD 等分析手段。 |

To confirm thermodynamic stability of the drug

substance, the risk of precipitation or salt formation during manufacturing

and storage should be evaluated. If there is an equilibrium between different

salt forms, the kinetics to reach this equilibrium should be thoroughly

characterized. The impact of this equilibrium on TDS performance should be

evaluated with relevant in vitro drug release, permeation, and/or clinical

data. |

|

||||||||||||||

|

产品特性研究-药物残留 |

透皮贴剂中药物的含量通常高于使用过程中的递送剂量以达到临床有效给药率。由于活性成分的浓度可能接近于其饱和极限,产品在贮存过程中存在药物结晶的风险,并对产品的质量和疗效产生潜在不良作用。此外,给药后透皮贴剂中残留的药物对患者、他人和环境都存在风险。 应对透皮贴剂的药物残留特性进行研究,并在临床阶段对残留量进行实际研究,而不应仅根据理论计算或文献数据评估。仿制药的药物残留量不应超过参比制剂,否则应对其合理性进行说明。 |

To provide a robust analysis of the residual drug, we

recommend the following: 1. Data should be based on analysis of the used TDS

and not on a theoretical calculation. 2. The amount of drug left on the skin surface should

be assessed. Any drug that may have been transferred to packaging or other

components of the TDS during storage or use should be accounted for in an

attempt to perform a mass balance. 3. Tape or overlays should not be used in studies

where the TDS is used to calculate residual drug. 4. TDS adhesion assessments should be conducted over

the entire period of wear to determine whether the TDS diffusional surface

area remains in full contact with the skin during the entire period of the

study. 5. A control study should be performed to provide an

estimate of drug load, rather than simply using the expressed label claim.

This study should include analysis of a minimum of three unused products from

the same lot of product used in the study. 6. Sample storage conditions before and after

application of the TDS on the skin should be validated. Photostability and

thermal stability of the active ingredient(s) in the TDS should also be

considered when selecting the appropriate storage conditions. 7. Appropriately sensitive and valid analytical

methods should be used to assay the residual drug content for the purpose of

calculating drug depletion and delivery. When estimating the amount of

residual drug in the TDS, a drug extraction method with a target extraction

efficiency close to 100 percent should be utilized to minimize error. |

|

||||||||||||||

|

产品特性研究-体外释放试验 |

体外释放试验(IVRT)是评估药物从透皮贴剂释放的速率和程度,是质量研究及稳定性考察中的重要指标。体外释放度可以载药量百分比表示,也可以(单位时间内)单位面积的药物释放量表示。 透皮贴剂体外释放度研究方法主要有桨碟法和转筒法,在中国药典、美国药典(USP)和欧洲药典(EP)中均有收载。此外,美国药典(USP)还收载了往复支架法,日本药局方(JP)收载了纵向扩散池法。 在建立体外释放度考察方法时,应对介质、pH 值、装置、转速等测定装置和测定条件进行筛选和优化,最终选择区分力适宜的测试条件,释放度方法需进行充分的方法学验证。 为了解产品的释放特性,通常应选取足够多的取样测试点,以绘制完整的释放曲线(包括上升曲线及达到平台的阶段)。前期取样点的时间间隔应较短,后期取样点时间间隔可相对延长,直至 80%以上的药物释放或达到平台期(每 2 小时取样 1 次,连续三个时间点药物释放无增加),整体考察时间可视制剂释放时间长短而定,一般不宜短于药物作用时间。 在释放曲线研究的基础上,释放度取样点应选取初始、中间和最终阶段每个阶段至少一个点,以载药量百分比表示为例,在任何时间点所允许的释放变化量应不超过限度平均值±10%,除非有临床批次证明其合理性。各点的释放度限度平均值应基于自制品的临床批次、注册/申报批和商业批(如有)数据的统计评估。放行和货架期的限度值应相同,除非有临床批次证明其合理性。 |

In vitro drug release testing of TDS products is

typically performed using specific, qualified apparatus such as: Paddle over

Disk, Cylinder, or Reciprocating Holder. The NDA or ANDA submission for the TDS product should

include a method development and validation report with complete

information/data supporting the proposed drug release method and acceptance

criteria. Sufficient detail and data should be included in the

method development and validation report so the adequacy of the method for

batch release and stability testing can be properly assessed. Examples of

parameters to evaluate during method development include selection of USP

apparatus/other equipment, drug release medium, rotation or agitation speed,

temperature, pH, sink conditions, use of a surfactant, and other technical

aspects of the test. An in vitro drug release method should be simple,

reliable, reproducible, discriminating, and robust. Applicants should strive

to develop a method that releases as much drug as possible. The validation section of the report should include

complete information/data regarding: i) the discriminating ability of the

selected method, ii) the validation of the drug release methodology, and iii)

the validation/verification of the analytical method selected to assay the

drug release samples. The selected method should be able to differentiate the

release profiles of TDS that are intentionally manufactured with meaningful

variations in critical process parameters and formulation components. Validation

data should demonstrate the range and sensitivity of the method for

proportional drug release across different strengths of the TDS. In addition,

validation data should demonstrate reproducibility of the method for drug

release across different runs of the same batch and its robustness, i.e., its

capacity to remain unaffected by changes in receptor medium temperature,

paddle rate, and other method parameters. The acceptance criteria for the in vitro drug release

test should be based on the proposed TDS product batch release data,

including data from bio-batches (e.g., BE, PK, Clinical),

registration/exhibit batches, and commercial batches (if available). To set

the acceptance criteria for the in vitro drug release test, a complete drug

release profile should be established by collecting data until there is no

increase in drug release over three consecutive time points (sampling every 2

hours). The drug release profile of TDS products typically encompasses

initial, middle, and terminal phases; thus, for setting the acceptance

criteria, there should be at least one sampling time point covering each

phase. The drug release data should be reported as the cumulative percent of

drug being released with time. The acceptance criteria range for each

specific timepoint should be based on the mean percentage value of drug

released ± 10 percent using the drug release data generated at these times.

The percentage should be determined based on the TDS product’s label claim.

If less than 100 percent drug is released, but no drug increase is observed

over three consecutive sampling timepoints (i.e., incomplete drug release),

the amount of drug reached at the plateau should be considered 100 percent

for the purposes of estimating the percent of drug release over time. Wider acceptance criteria range for the drug release

test may be acceptable if they are supported by an approved in-vitro in-vivo

correlation model. |

An in vitro release test evaluates the rate and

extent of release of an active substance from a transdermal patch. Although

the test may not model in vivo performance, it is a critical quality

attribute to be specified in the finished product release and shelf life

specification. The methods described in Ph. Eur. monograph for

Transdermal Patches should be followed i.e. a dissolution test or a release

test using an appropriate, non rate-limiting membrane. If appropriate,

alternative methods, with improved discriminative power compared to the

compendial methods, may be employed. The test itself and / or sample preparation should

not damage or otherwise alter the performance of the transdermal patch. Any

special requirements for sample preparation should be discussed. It may be

possible to test only a defined sample area of patch which is applicable to

all strengths, if it is shown that sample preparation has no impact on drug

release / dissolution. If the size of the patch is too large to be inserted

into standard dissolution testing apparatus or if sink conditions cannot be

achieved using entire patches, suitability of testing specimens might be

inferred from dose proportionality studies for samples of different size. The in vitro drug release / dissolution profile of

the active substance from the drug product should be characterised and

established from clinical batches for which satisfactory efficacy has been

demonstrated. These should be used to support the in vitro drug release /

dissolution limits in the drug product specification (3.2.P.5.6), and so

provide an assurance that future production batches are of similar quality to

the pivotal clinical batches. Satisfactory evidence of discrimination should be

provided, with respect to: · Critical manufacturing variables; · Excipient and active substance critical

quality attributes; and · The stability indicating power of the

method. A summary of the development of the dissolution test

should be provided, where the transdermal patch is tested under various

conditions (media, pH, apparatus, agitation, etc.). Testing conditions

providing the most suitable discrimination should be chosen. In case of media

with a low buffering capacity, the pH should be controlled during the

dissolution test to avoid influence of the dissolved active ingredient and/or

excipients on the dissolution conditions during the test period. The test period should be sufficient to achieve

complete drug release, unless justified. For the release / dissolution profile, the number of

sampling time points should be sufficient to obtain meaningful profiles, with

more frequent sampling during the period of greatest change. At least 3 sampling time points are recommended to

give a sharper and more differentiated profile. An early time point to exclude dose dumping and/or to

characterise a loading/initial dose (typically 20 to 30% dissolved), at least

one point to ensure compliance with the shape of the dissolution profile

(around 50% dissolved) and one to ensure that the majority of the active

substance has been released (generally more than 85% dissolved i.e. Q=80%). For most matrix type patches earlier sampling times

(between 0 to 1 hour) were found to be more discriminative, i.e. quality

indicating than later time points, when already up to 50% of active substance

is released from the patch. Changes in formulation or manufacturing

parameters are more likely to be detected within the first hour of in vitro

dissolution testing if the specification ranges are set in accordance to the

requirements listed below. For the dissolution profiles, the value to be

reported at each time point should be the quantity of active substance

released in mass units (mg or μg) per surface area. The quantity of active

substance should also be reported as a % of the total. In addition, the first derivative of this profile

should also be reported, to allow assessment of the change in the rate of

release over time i.e. the value to be reported at each time point should be

the quantity of active substance released per surface area, per time. For transdermal patch products showing an in vitro

zero order release (e.g., which may be seen in those patches with a

rate-controlling membrane) a specification of the dissolution rate at a given

time point may be more appropriate than the cumulative amount dissolved at a

given time point. The number of samples used to characterise the

dissolution profiles should normally be a minimum of 12 units per batch (for

routine release, a minimum of 6 units would be accepted). Dissolution profile data should be provided in

tabular and graphical formats, with a measure of variability between units

e.g., 95 % confidence interval, range, or other justified statistical

approach. The dissolution profiles should be discussed taking

into account the type of transdermal patch. Dissolution limits should be data driven and fully

justified. They should be characteristic of production capability and in line

with clinical batches for which satisfactory efficacy has been demonstrated. Normally, the permitted range in mean release at any

given time point should not exceed a total numerical difference of ±10% of

the labelled content of active substance (i.e. a total variability of 20%: a

requirement of 50±10% thus means an acceptable range from 40-60%), unless a

wider range is supported by a bioequivalence study. Wider limits may be accepted only if satisfactorily

explained and justified on quality grounds and supported by a bioequivalence

study. Release and shelf life limits should normally be the

same, unless the reasons for the differences are satisfactorily explained on

quality grounds and justified by reference to clinical batches. Tighter

limits at release should be set to ensure that the product will remain within

the shelf life specification. |

||||||||||||||

|

产品特性研究-体外透皮试验 |

体外透皮试验(IVPT)是为了模拟药品在生理条件下的透皮过程,以部分地反映药品的质量与临床治疗的有效性。应在体外透皮试验方法系统的研究及验证基础上,对仿制药与参比制剂进行皮肤透过率的对比研究。 体外透皮试验目前主流方法为 Franz 扩散池法(Diffusion cells),也可采用流通池法(Flow Through Cell)或其他经过方法学研究证明可行的体外透皮试验方法。 在建立体外透皮试验方法时,应对接受介质、温度和转速、皮肤种类与部位以及皮肤完整性进行研究,选择具有适宜区分力的试验条件开展体外透皮试验研究。 |

In vitro permeation testing (IVPT) with the use of

excised human skin may be utilized to characterize the rate and extent of

transdermal or topical drug delivery, and the study protocols and results

should be described in the application. The following factors should be

considered during IVPT model development: · Selection of the diffusion apparatus and

the operating conditions like stirring rate or flow rate, as well as

temperature control to maintain the under-normal-conditions skin surface

temperature (32°C ±1°C) · Source of the skin, skin storage

conditions, choice of skin type (i.e., age range, sex , race, and consistent

anatomical region) and the skin preparation technique (e.g., full-thickness,

dermatomed, isolated epidermis) The IVPT protocol should specify the nominal skin

thickness and its range, details of the skin barrier integrity test, and any

occlusion of the product during the IVPT. Visual observations alone are not

sufficient to characterize the barrier integrity of the skin. Acceptable

barrier integrity tests may be based on tritiated water permeation,

trans-epidermal water loss (TEWL), or electrical impedance/conductance

measured across the skin. The test parameters and acceptance criteria used

for the skin barrier integrity test should be justified based on relevant

literature references or other information. The IVPT protocol should also include details about

the receptor solution, system equilibration, procedures for skin mounting and

application of the TDS, as well as any measures to secure the TDS on the skin

surface to prevent lifting. We recommend that an antimicrobial agent be

included in the receptor solution (e.g., ~0.1 percent sodium azide or ~0.01

percent gentamicin sulfate). The IVPT study report should include dose duration,

sampling duration, sampling time points, concentration of samples,

concentration of the antimicrobial component, and the empirical stability (at

relevant temperatures) and solubility of the active ingredient in the

receptor solution. The study report should also include the number of

individuals whose skin was evaluated (i.e., skin donors) and the number of

replicate skin sections per donor per treatment group. All treatment groups compared in an IVPT study should

be dosed on the skin samples from the same set of donors, with the same

number of replicates per donor per treatment group. These treatment groups

should also use the skin samples from the same anatomical site from all

donors, unless varying these parameters is essential to the design of the

study and the evaluation of the TDS. The study report should include the

equilibrated skin surface temperature prior to dose application, and the

ambient temperature and relative humidity in the laboratory, as well as the

extent of qualification of the sample analytical methods (e.g., HPLC). |

1. Introduction Percutaneous/dermal absorption describes the passage

of compounds across the skin: · Penetration which is the entry of a

substance into a particular layer or structure such as the entrance of a

compound into the stratum corneum; and · Permeation which is the penetration

through one layer into another, that is both functionally and structurally

different from the first layer. In vitro permeation studies are often used throughout

pharmaceutical development to evaluate the permeation of an active substance

from a transdermal patch. A major advantage of in vitro studies is the

possibility for controlling the conditions of the experiment and therefore

changes in permeation should only arise from changes in the transdermal patch

and/or the membrane used. In vitro permeation studies are not expected to

correlate with in vivo release, but the characterisation of the permeation

profile is considered a valuable measure of product quality and performance

and may reflect the thermodynamic activity of the active substance in the

product. Establishing the characteristic permeation profile of

the drug product, using a discriminative in vitro skin permeation method, can

be of value in change control during life cycle management. For the comparison of products, the need to perform

bioequivalence studies may, in certain cases, potentially be waived. However,

given that the product formulation may have a great impact on efficacy and

modify skin permeation, the products to be compared should have the same or

similar qualitative and quantitative excipient composition. In line with the requirements for in vitro drug

release / dissolution methods, satisfactory evidence of discrimination and a

summary of the development of the permeation test should be provided. It is recommended to use human skin from the torso

(breast, abdomen or back) or relevant to the site of clinical application.

However, if not possible, non-viable skin or skin from other species (such as

pig, rodent, guinea pig) can be used. In some cases, artificial/synthetic

membranes can be suitable. The choice of skin model used throughout the

development should be justified. In the case of a comparative test (development of a

generic transdermal patch or formulation comparison), it is necessary that

the products are compared with the same skin type. The skin type, preparation and storage are elements

that should be satisfactorily controlled, and that the skin samples for

experiment are not damaged by these processes and are of suitable quality. The integrity of the skin should be determined before

the experiment and shown to be satisfactory for the experiment to be valid. A variety of integrity tests is currently available,

e.g., measurement of Transepidermal Water Loss (TEWL), monitoring the

permeation of tritiated water or measurement of electrical resistance. The

suitability of integrity test for the proposed experiment and criteria for

acceptability should be fully discussed. To address the variability of skin, preparation and

skin integrity, a sufficient and justified number of replicates should be

included in the experiment. Typically, six replicates may be used, or more

for pivotal experiments. In vitro permeation studies are usually performed

using diffusion cells, with a skin diffusion area between 0.5-2 cm2.

Diffusion cells with larger skin diffusion areas should be used for

transdermal patches that cannot be cut to size, e.g., reservoir type patches.

Diffusion cells should be inert, robust and easy to handle. It is also

important that the diffusion cell provides easy sampling and replenishment of

the receptor phase and that it maintains the membrane integrity. The most

common diffusion cells are Franz-type (static) cells, which consist of two

chambers that can be side-by-side or upright separated by the skin. Flow

through cells can also be used and are particularly useful to maintain skin

viability. The receptor solution used should mimic the in vivo

conditions. One appropriate receptor medium for water soluble drugs is

aqueous buffer. Solubilising agents e.g., surfactants or hydro-alcoholic

media e.g., ethanol/water media, or protein e.g., bovine serum albumin can

also be used in the case of drugs that are less soluble in water, if

justified. The liquid in the receptor compartment has to be in contact with

the skin, i.e., it should be ensured that there are no air bubbles under the

skin. The receptor solution should not affect skin

integrity. Permeation of solubilising agents from the receptor

solution into the skin sample should be considered and avoided. The composition of the receptor medium should be

described and solubility studies to demonstrate that sink conditions can be

maintained throughout the experiment should be submitted. The active substance should be stable in the receptor

solution for the duration of the test and subsequent analysis. The receptor solution should provide solubility sink

conditions throughout the experiment and ensure that the permeation of the

active substance is not limited by the receptor medium. An acceptable sink

condition is one where the maximum concentration of the active substance in

the receptor solution achieved during the experiment does not exceed 10-30%

of its maximum solubility in the receptor solution. Sink conditions can be

maintained during the experiment in static cells by continuous replacement of

the receptor phase or by using a flow through system. For satisfactory permeation, satisfactory means

should be in place to ensure that the receptor medium is fully in contact

with all the exposed skin. The diffusion of the active substance through the

membrane is evaluated measuring the arrival of drug in the receptor

compartment by assay of sequentially collected samples of the receptor fluid. Aliquots of the receptor fluid can be analysed by a

validated HPLC or LC-MS for active substance content or by any other suitably

validated analytical technique. It is acknowledged that the variability in results

seen with in vitro skin permeation data is related to the variability in the

skin used. In addition, if these methods are poorly developed, without

satisfactory validation and / or poorly executed, then the results from

permeation studies can only be difficult to interpret or without merit or

meaning. Therefore, method development, optimisation and execution should

comply with known best practice, be satisfactorily validated, and subject to

appropriate data analysis and quality assurance principles. 2. Skin and sample preparation The following should be described and their

suitability discussed: · The type of skin (origin, species, part of

the body) should be stated; · The storage and transport of the skin

should be described and appropriately controlled; and · The preparation and treatment (thickness,

separation) of the skin should be described and justified. The integrity of the skin should be determined before

the experiment and shown to be satisfactory for the experiment to be valid. Sample preparation of the drug product transdermal

patch should be described and its suitability discussed. Normally, the patch

is carefully cut to size and applied to the skin in the donor chamber. In

case overlays are used, the effect of occlusion should be investigated. The test itself and / or sample preparation should

not damage or otherwise alter the performance of the transdermal patch. 3. Study design / study conditions The following study design is recommended for

permeation studies using ex vivo human skin. Any deviations from the proposed

test protocol should be fully justified. · Diffusion cell – Franz type or flow

through; · Receptor phase, to mimic in vivo

conditions that also provides active substance sink conditions, degassed,

e.g., in an ultrasound bath to prevent the build-up of air pockets; · The medium may be aqueous buffer and

include justified solubilising agents and / or protein; · Receptor phase should be continuously

agitated and remain in contact with the skin. The stirring speed should be

justified; · Temperature - the surface of the skin, in

the diffusion cell, is maintainable at a temperature close to the

physiological human skin temperature (32°C±1°C). The skin surface temperature

may be suitably verified prior to dose application using an infrared

thermometer; · Humidity – Extremes of relative humidity

in the laboratory should be avoided, i.e. above 70% RH and below 30% RH; · Human skin integrity should be tested at

the beginning of the experiment; · The suitability of integrity test e.g.,

(TEWL), permeation of tritiated water, electrical resistance or visual

inspection (but not accepted for pivotal studies) and criteria for acceptance

should be fully discussed; · Number of replicates – The choice of the

number of samples should be justified with regard to the scope of the

experiment and demonstrated to be statistically relevant; · Number of skin donors – at least 2

different donors; · Skin anatomical region –torso (breast,

abdomen or back) or relevant to the site of clinical application; · The number of time points should be

sufficient to satisfactory characterise the permeation profile. Minimum of 5

suitably timed receptor sampling time points and an early time point, based

on study requirements; · Study duration should be justified in

regards to the in-use administration. If the study duration is longer than 24

hours, it should also be shown that skin barrier function and integrity is

adequately maintained; and · Un-occluded conditions, in case overlays

are used the effect of occlusion should be investigated. 4. Method development and validation A summary of the method development and optimisation

should be provided. The most appropriate receptor medium for water

soluble drugs is aqueous buffer. Hydro-alcoholic medium or indeed any other

appropriate medium can be used in the case of drugs that are sparingly

soluble in water, provided that it is justified. Testing conditions providing

the most suitable discrimination should be selected. The composition of the

receptor phase should not influence the permeation of drugs, should ensure

sink conditions and should not alter the membrane. The method should be suitably discriminating. The

following should be considered: · It is discriminating between batches with

respect to critical manufacturing parameters that are known to have an impact

on the bioavailability of the product. · It is discriminating between products

formulated at different concentrations, and altered formulations (e.g., drug

content, permeation enhancer). · The stability indicating power of the

method should be assessed. The analytical methods for determining the content of

active substance in the receptor fluid and mass balance determinations should

be provided and validated according to ICH Q2(R1). The reference standards used during the validation

and study sample analysis should be obtained from an authentic and traceable

source. The method validation should also address the

variability of the method and the coefficient of variation established. For

artificial membranes, the coefficient of variation should be less than 10%,

for human skin a coefficient of variation greater than 10% can be accepted. 5. Data analysis Data from all diffusion cells should be reported and

the validity, variability and reproducibility of the results should be

discussed. The results should be subject to an analysis of variance. Outliers may be excluded from the statistical

analysis, if satisfactorily explained and justified. The plot of the

cumulative amount of drug permeated per unit area (mass/cm2) as function of

time should be presented. The slope of the curve represents the permeation

rate (flux) of the drug. The permeation profile should be supported with

tabulated data and statistical analysis. The permeation rate (flux) should be

calculated for each diffusion cell and the mean flux reported together with

the corresponding standard deviation (SD), coefficient of variation. A discussion, interpretation and conclusions of the

results of the experiment should be provided, supported, as necessary, by

appropriate scientific rationale. For the comparison of products, relevant permeation

parameters, e.g., flux, should be statistically compared. The 90% confidence

interval for the ratio of the two products should be determined and should be

contained within the ratio of 0.8 to 1.25 to support a claim of equivalence,

unless justified. The method should be based upon a null hypothesis of non

equivalence. 6. Quality system and study report It should be ensured that the performing laboratory

is qualified to perform the studies and that an effective quality system is

in place. This should include: · A declaration of compliance with a

suitable quality system, e.g., GMP (Directive 2003/94/EC); · The technical ability of the performing

laboratory and the validity of the method used should be assessed at regular

intervals, at least twice per year, by using reference compounds like

caffeine or benzoic acid. The recent results of such studies should be

provided; · The laboratory should be subject to

external audit e.g., by the Marketing Authorisation Applicant or a suitable

accreditation body; and · Audits certificates, if available. |

||||||||||||||

|

产品特性研究-可提取物和可浸出物 |

|

All TDS should be evaluated for potential compounds

that could be transferred from the product to the patient. This evaluation

should include assessments of extractables and leachables, consistent with

USP <1663> and <1664>. In the context of this guidance, extractable

impurities are chemical entities that can be drawn out of the backing

membrane, release liner, pouching material, printed ink, internal membranes,

and components other than the drug substance and adhesive matrix by a solvent

system. Additionally, an extraction study can detect compounds introduced

into the TDS from the manufacturing process, which can impact the final

impurity profile of the TDS product. In the context of this guidance,

leachables are chemical entities present in a packaged TDS because they

leached into the adhesive matrix (or where applicable, reservoir) under

normal conditions of storage or during accelerated stability studies. These

compounds may transfer from the adhesive matrix (or reservoir) to the patient

during use. i. Extractable Studies Extractable studies should be conducted early in the

pharmaceutical development process to understand the potential leachables

from components of the proposed commercial TDS. These studies should be

conducted on components such as backing membrane, release liner, rate

controlling or other internal membranes, ink and pouching. The testing

components should be extracted in a variety of solvents with a range of

polarities under vigorous laboratory extraction conditions to maximize the

levels of extractables and identify as many potential leachables as possible.

One of the extraction solvents used in the extractable studies should include

the solvent of the proposed commercial adhesive(s) platform or the known

residual solvents for the finished TDS. The choices of solvents used should

be justified. ii. Leachable Studies The conditions of the leachable studies should mimic

as closely as possible the “worst-case” clinical conditions of the skin

(e.g., sweating during rigorous exercise). The solvent/solution selection

(such as salt concentrations), temperature, level of agitation, duration of

exposure to the solvent, etc., selected for the studies should be justified.

The release liner should be removed from the system during the study to

adequately expose the adhesive layer to the biologically relevant solvent.

Applicants should conduct a multi-timepoint leachable analysis (e.g., 0, 6,

12, 24 months) to provide a comprehensive leachable profile and identify any

trends in leachables as these data could impact the shelf life of the

product. At the time of application submission, data should be submitted from

a leachable study performed on samples from multiple batches stored at a

minimum of 6 months under accelerated and long term conditions. We recommend

conducting leachable studies on the same three distinct laminates of TDS placed

on stability testing. |

|

||||||||||||||

|

产品特性研究-评估热效应 |

应考虑各种因素导致的体温升高对药物(特别是治疗窗较窄的药物)释放速率及透皮性能的影响,必要时进行相关研究,以评估仿制药与参比制剂的变化趋势是否一致。 |

Heat from external sources such as a heating blanket,

and potentially from a rise in internal body temperature due to strenuous

exercise or fever, may affect the rate of drug release from the TDS and the

absorption of drug into and through the skin. We recommend that applicants

study the impact of an elevated TDS/skin surface temperature on the delivery

profile of TDS relative to its delivery profile at a normal TDS/skin surface

temperature. For a TDS product to be submitted in an NDA, we

recommend that the heat effect studies be conducted as part of a clinical

study using the proposed commercial product. In designing the heat effect

studies, critical factors such as appropriate elevated test temperature(s),

heat exposure onset time(s), duration(s), and cycles (if any), as well as

mechanisms of heat exposure (e.g., heating lamp, heating pad, etc.) should be

identified. For a TDS product to be submitted in an ANDA, the

applicant should evaluate whether the test TDS, used under elevated

temperature conditions, increases drug delivery compared to the reference (R)

TDS. The ANDA applicant should provide the results of an IVPT study comparing

the drug delivery characteristics for the test TDS and the R TDS at normal

and elevated temperatures using skin from multiple individuals (donors), with

multiple replicate diffusion cells evaluated per donor, per treatment (test

versus R), and per temperature condition. An IVPT study with a sufficient

number of donors and replicates per donor per treatment per temperature

condition is recommended to obtain meaningful data. A study with fewer than

four donors and four replicates per donor per treatment per temperature may

be difficult to interpret. We recommend a parallel evaluation and comparison of

the test and R TDS under the following baseline and elevated temperature

conditions: 1. BASELINE: Both the test and R products should be

maintained at a TDS/skin surface temperature of 32 ±1°C for the entire study

duration. 2. ELEVATED TEMPERATURE: Both the test and R products

should be maintained at a TDS/skin surface temperature of 32 ±1°C until a

specified time, approximately when the peak flux is observed, and then

maintained at a TDS/skin surface temperature of 42 ±2°C for a period

thereafter, which may be the remainder of the study duration. It should not be assumed that a set temperature for a

circulating water bath will provide the target temperature at the TDS/skin

surface. The TDS/skin surface temperature should be directly measured using

an infrared thermometer or other temperature probe. The study duration for a

7- day wear TDS need not encompass the entire labeled duration of wear. It

may be adequate to perform an IVPT study for a 48 or 72 hour duration, if

that duration is sufficient to reach the peak drug delivery rate under baseline

conditions. Alternatively, an applicant may justify evaluating other

conditions or scenarios of exposure to elevated temperatures that represent

the worst-case scenario for a given TDS product or indicated patient

population. i. Microscopic Matrix Evaluation Due to complexities of many TDS formulations,

adhesive matrices often do not form true solutions, rather they manifest as

dispersions. If rearrangements of the dispersed-like system occur over time

within the matrix, they can possibly lead to lack of adhesion or changes in

drug delivery and release. As such, it is important to have a good

understanding of the TDS formulation, the way the drug substance and

excipients are dispersed within the adhesive matrix, and the tendency of the

matrix to change over time from product release through its expiry period.

Therefore, it is informative to assess surface and cross-sectional changes in

the TDS matrix throughout the shelf life of the developmental batches using

high-powered microscopy, elemental mapping, or other appropriate tools. These

tools may not be appropriate for every TDS; applicants should provide a

scientific justification for the tools used. These assessments will help

achieve comprehensive understanding of product and process, mitigate

quality-related risks, and assure that the TDS meets the requisite quality

attributes through its expiry period. |

|

||||||||||||||

|

产品特性研究-体外粘附性能 |

剥离强度:将透皮贴剂在规定压力下施用于标准基板,在指定的温度和时间下进行平衡,然后使用仪器将透皮贴剂从基材上剥离并记录相应的力。 保护层剥离力:用成品样品进行,在指定的温度和时间下进行平衡,然后使用仪器将保护层从透皮贴剂上剥离并记录相应的力。 初黏力:可采用滚球法、探针法或其他替代方法测定。 持黏力:可进行动态和静态测试。在动态测试期间,可将透皮贴剂以恒定的速率从测试面板上拉出。进行静态测试时,可通过悬挂砝码来测试透皮贴剂的承受剪切力。 冷流:冷流是透皮贴剂固有的特性,大小通常取决于药品处方、包装设计、贮存条件和时间。应重视处方的流变学研究,并采用定量和定性相结合的方法评估冷流。 黏附性能的限度范围应根据产品开发、稳定性考察及临床试验等多个产品批次的统计评估,确保各批次之间的黏附性能一致。 |

Using currently available methods, in vitro adhesion

testing does not correlate to in vivo adhesion, but in vitro adhesion testing

can be useful for quality control (QC) purposes. In vitro adhesion testing

should include peel adhesion, release liner removal, tack, and shear (dynamic

or static). The peel adhesion test measures the force required to

remove (peel away) a TDS that has been applied to a standard test panel

(e.g., polished stainless steel). The measurement of peel adhesion is

influenced by the test parameters such as dwell time, substrate (e.g.,

stainless steel, high density polyethylene (HDPE)), peel angle, and peel

speed. A release liner peel test measures the force required

to separate a TDS from its release liner. The measurement of release liner

peel is influenced by experimental parameters such as peel angle and peel

speed. The probe tack test measures the force required to

separate the test probe from the adhesive of the TDS. Tack measurement is

influenced by the test parameters such as the contact area, the contact

pressure, the time of contact (or dwell time), and rate of separation. There are two categories of shear testing, namely

dynamic and static. In the dynamic test, the TDS is pulled from a standard

test panel (e.g., polished stainless steel). Dwell time, speed, type of test

panel, mode of failure, and sample size are the typical test parameters

reported for the dynamic shear test. In the static shear test, the TDS sample

is applied to a test panel that is at an angle 2° from the vertical, and the

sample is subjected to a shearing force by a means of a given weight (e.g.,

1000 g) suspended from the TDS; the time required to detach a standard area

of the TDS from a stainless steel test panel under a standard load is

measured. Dwell time, weight used, type of test panel, mode of failure, and

sample size are the typical test parameters reported for the static shear

test. The time taken for the TDS sample to detach from the test panel is also

reported. Cold flow is the creeping or oozing of the adhesive

matrix beyond the perimeter of the backing membrane or through the release

liner slit. Cold flow may be present on the TDS, release liner, pouch, or

disposable films (sometimes termed slip sheets or protective films, such as a

film over the backing and a film over the release liner). Though a

quantitative method of assessing cold flow can provide a meaningful

measurement, it may not describe the difficulty in removing the TDS from the

pouch or the protective films from the TDS. The most accurate cold flow

assessment for TDS will likely come from a combination of product-specific

quantitative and qualitative methods. |

In vitro adhesive tests should characterise the

adhesion/cohesive properties of the transdermal patch. Although these tests

may not model in vivo adhesion, they are critical quality attributes to be

specified in the finished product release and shelf life specification. Tests to characterise adhesive properties may

comprise tests such as peel force tests (force required to remove the patch

from the release liner), adhesive strength tests (force required to remove

the patch from a defined surface) and tack tests (maximum force required to

break a bond formed under low pressure between the adhesive layer of the

patch and a stainless steel probe). Residue remaining on the release liner after peeling

from the patch and skin residues, following transdermal patch removal, should

also be addressed. The range and sufficiency of the in vitro tests used

to characterise the adhesive properties of the drug product should be

justified. A summary of their development should be provided to support any

justification, if necessary. The suitability and discriminatory power of the test

methods employed to characterise the adhesive properties of the drug product

need to be proven during product development, in particular with respect to: · Critical manufacturing variables; · Excipient and/or active substance critical

quality attributes; and · Stability indicating power of the method. The in vitro adhesive properties of the drug product

should thus be characterised, with the specifications limits for the

specified tests in accordance with the results obtained on clinical batches

for which satisfactory in vivo adhesive properties under product use have

been demonstrated and used to support their justification of the drug product

specification (3.2.P.5.6) (see also Section 4.2.9 Administration). Release and shelf life limits should be the same,

unless justified by reference to clinical batches. |

||||||||||||||

|

产品特性研究-体内粘附性能 |

|

In vivo adhesion studies provide the greatest

prediction of adhesion, a CQA, for a proposed commercial product. Applicants

should demonstrate that reasonable efforts were made to optimize adhesive

characteristics of the TDS. This optimization should balance properties such

as adhesiveness, cohesiveness, and stability to ensure a consistent and

uniform adhesion of its entire surface area to the skin for the entire

duration of wear. Applicants should develop a comprehensive strategy for

assessing the adhesive attributes of the TDS. In vivo adhesion studies are

necessary to demonstrate adequate adhesion of the TDS. Therefore, when

possible, such as in efficacy studies for an NDA, subject diaries describing

the actual in-use product adhesion performance should be used. This

information bolsters adhesion data collected from the studies described below

and in other guidances. Characterization of the adhesive properties of a TDS

should demonstrate that the labelled uses are substantiated. For example, if

the TDS is intended to be worn during bathing and showering, applicants

should demonstrate that the TDS will continue to adhere during and after such

incidental exposure to water. Product reinforcement, such as taping the edges

or use of overlays, or occluding the product from water during bathing should

not be permitted during the in vivo adhesion evaluation. We recommend that when assessing the adhesion of a

TDS, applicants use a 5-point numerical scale in which each score corresponds

to a specified range of adhered surface area of the TDS, as follows: 0 = ≥ 90% adhered (essentially no lift off the

skin) 1 = ≥ 75% to < 90% adhered (some edges only

lifting off the skin) 2 = ≥ 50% to < 75% adhered (less than half

of the TDS lifting off the skin) 3 = > 0% to < 50% adhered (not detached, but

more than half of the TDS lifting off the skin without falling off) 4 = 0% adhered (TDS detached; completely off) Additionally, the following information should be

collected: · At each time point when adhesion is

assessed on the above described 5-point scale, the scorer should also record

their actual percent adherence estimate (e.g., if the observer scores the

product as a two on the five point scale and estimates that the product

appears to be 60 percent adhered, a score of two and a 60 percent should be

recorded for that time point). · Photographic evidence showing the extent

of TDS adherence to the skin at each time point should be provided. |

Studies to investigate and establish the satisfactory

in vivo adhesive performance of the drug product should be undertaken. Since an in vivo adhesion study is pivotal for

approval, a feasibility or pilot study could be helpful in ensuring the

methods can be satisfactorily undertaken, producing result from which valid

conclusions can be made. The assessment should be undertaken throughout the

proposed period of use of the patch. This is because satisfactory adhesion

performance of the clinical batches used would be a requirement for any

clinical conclusions to be valid (see also Guideline on the Pharmacokinetic

and clinical evaluation of modified-release dosage forms). The clinical batches should be representative of the

product to be marketed (see Section 4.2.6.5 Product Batches used in Clinical

Studies). Reference to the in vivo adhesion studies described

in the clinical dossier should be provided. |

||||||||||||||

|

产品质量控制项目 |

应根据产品特点制订质量控制项目,除通用质量控制项目(如性状、鉴别、含量、单位剂量均匀性、有关物质)外,还应至少包括体外释放及黏附性相关的检查项。相关项目的可接受标准应结合参比制剂测定结果,依据自制品临床代表性批次质量研究数据与稳定性数据制定。 |

Typical CQAs included in TDS specification: · Description · Identification · Assay · Impurities and degradation products · Uniformity of dosage units · Permeation enhancer content, when

applicable · Adhesion · Release liner peel · Tack · Shear · Cold flow · In vitro drug release · Drug substance crystal presence · Pouch integrity · Microbial limits, when applicable · Moisture content, when applicable · Residual solvents |

The scope of the specification should comply with

Pharmacopoeial and relevant ICH guideline requirements, and should include

appropriate performance tests with respect to in vitro release / dissolution

and adhesion (see Section 4.2.6.1 In vitro drug release / dissolution and

Section 4.2.6.3.1 Adhesive Properties in vitro tests). The appearance of the

transdermal patch should also be fully specified. The limits should be in line with representative

batch and stability data, unless suitably qualified by non clinical, clinical

or other data. Limits for performance tests should be justified by

reference to clinical batches for which satisfactory efficacy and safety has

been demonstrated. The limits should be the same at release and shelf life,

unless justified and qualified by clinical data. |

||||||||||||||

|

申报批次生产要求 |

|

Applicants should submit data for registration/exhibit

batches manufactured from three distinct laminates, where each laminate is

made using different lots of drug substance, adhesives, backing, and/or other

critical elements in the TDS product. |

|

||||||||||||||

|

仿制药要求 |

研究者应当按照国家局发布的《化学仿制药参比制剂遴选与确定程序》选择参比制剂。仿制药的产品规格应当与参比制剂相同,关键质量特性也应不低于参比制剂。 仿制药与参比制剂相比,载药量和贴剂面积可能有所不同,但通常应具有相同或更高的贴剂面积活性(Patch Area Activity),且应确保在相同时间内递送的剂量相同,并应尽可能减少贴剂中的药物残留。 |

|

With respect to drug product quality, the following

elements should be compared: · Strength, as the mean dose delivered per

unit time, normally mass delivered in vivo per hour; · The content and location of active

substance in the drug product; · In vivo release rate or strength per patch

area (i.e. mass delivered in vivo/unit area/unit time); · Active substance utilisation (% of total

active substance absorbed per patient administration); · Patch area activity (active substance

utilisation/patch area); · Residual (mass of active substance

remaining in the drug product after completion of administration); · Instructions for use, including the use of

any overlay; and · Period of use. With respect to in vitro performance: Comparative drug release / dissolution, in vitro skin

permeation and adhesion / cohesive properties should be investigated and the

differences and similarities in in vitro performance between the generic and

reference products should be discussed, supported by appropriate data. For a generic or abridged application, the product

strength must be the same as the reference product. The other quality

elements, given above, should also be the same or similar, unless fully

justified. Clinical: To support a generic or abridged application,

bioequivalence with the reference product and also noninferiority (absence of

statistically significant difference) with respect to in vivo skin adhesion

should be demonstrated. Non-inferiority regarding clinical safety and local

tolerance of the generic product should also be demonstrated. |

为帮助审核人员更快处理,请填写举报原因:

为帮助审核人员更快处理,请填写举报原因: